Technology

Our unique engineering approach includes all process steps incl. CVD diamond growth, NV creation and quantum characterization.

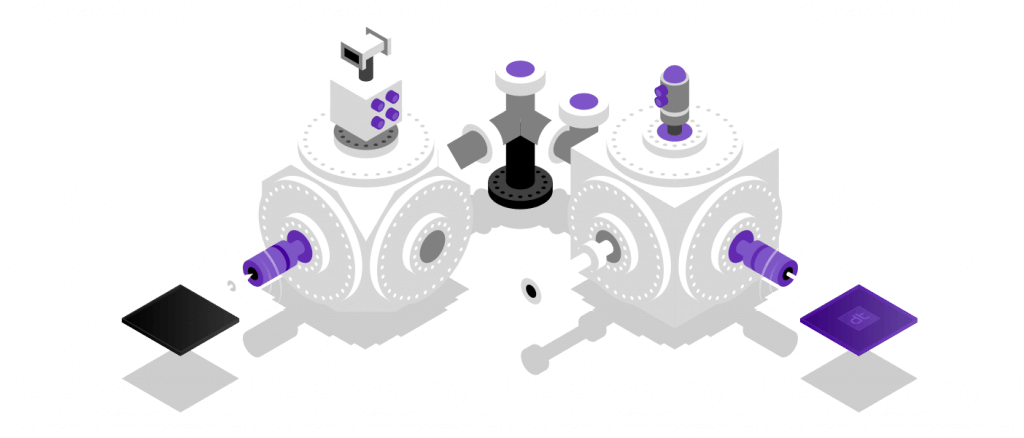

The world's first quantum diamond production line

By building the world’s 1st production line for quantum diamond „Made in Germany“ we centralize all necessary processing steps. Our facility includes CVD diamond growth, ion implantation as well as high temperature annealing in vacuum for final creation of NVs and other color centers. The individual components are custom built and optimised for their use in quantum diamond technology. Proprietary and patented production recipes complete our broad range of competences.

Typical production process

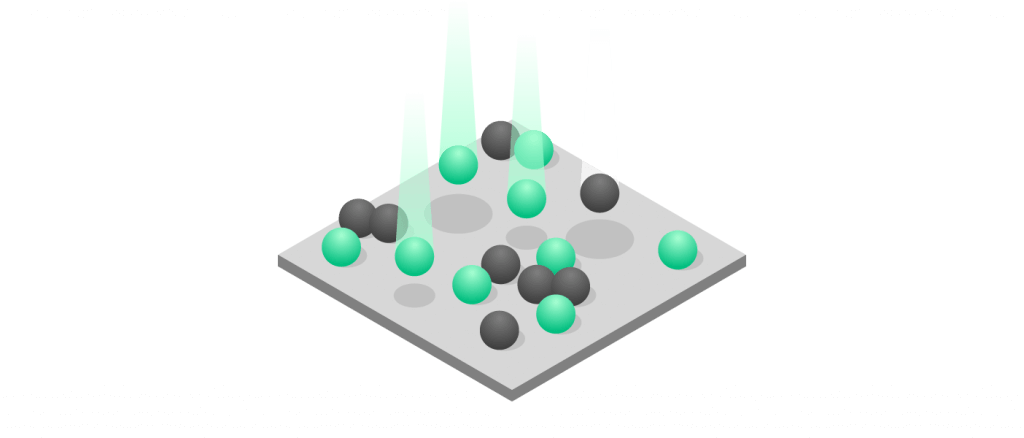

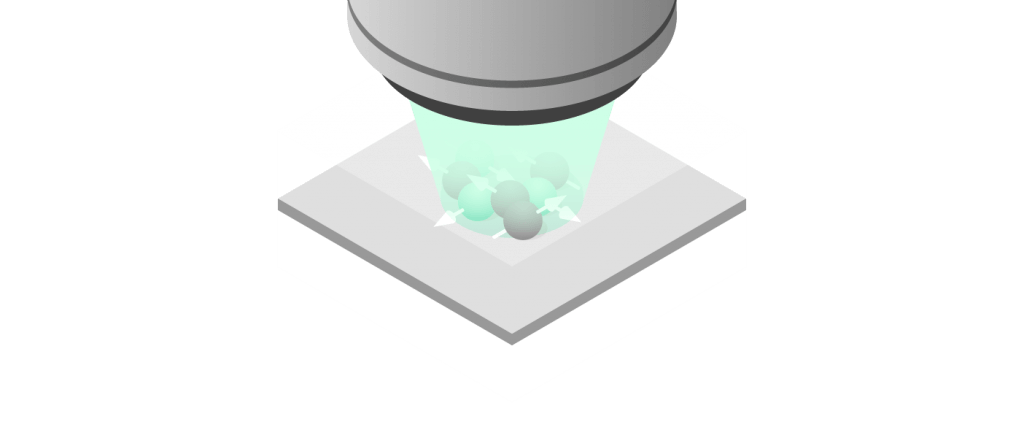

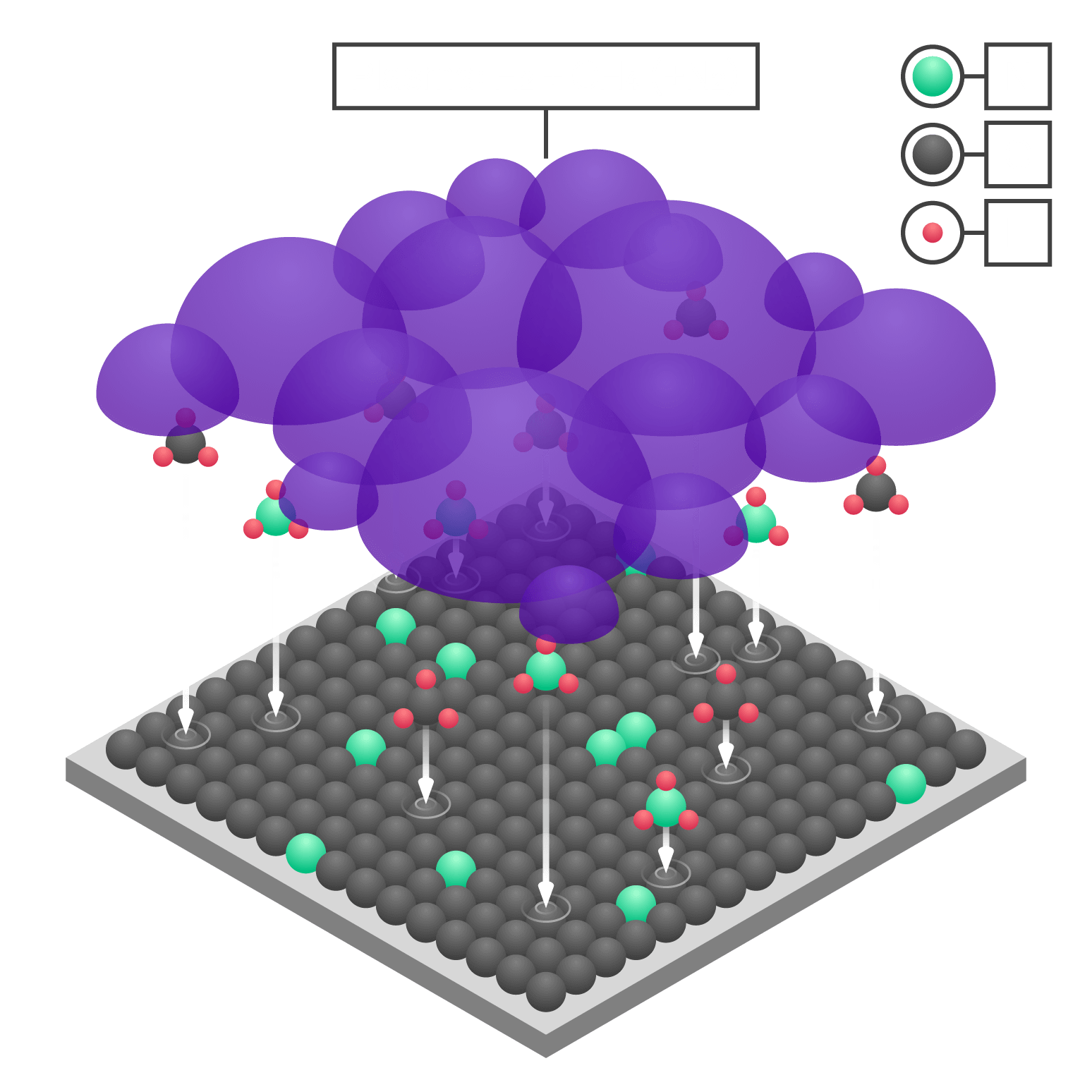

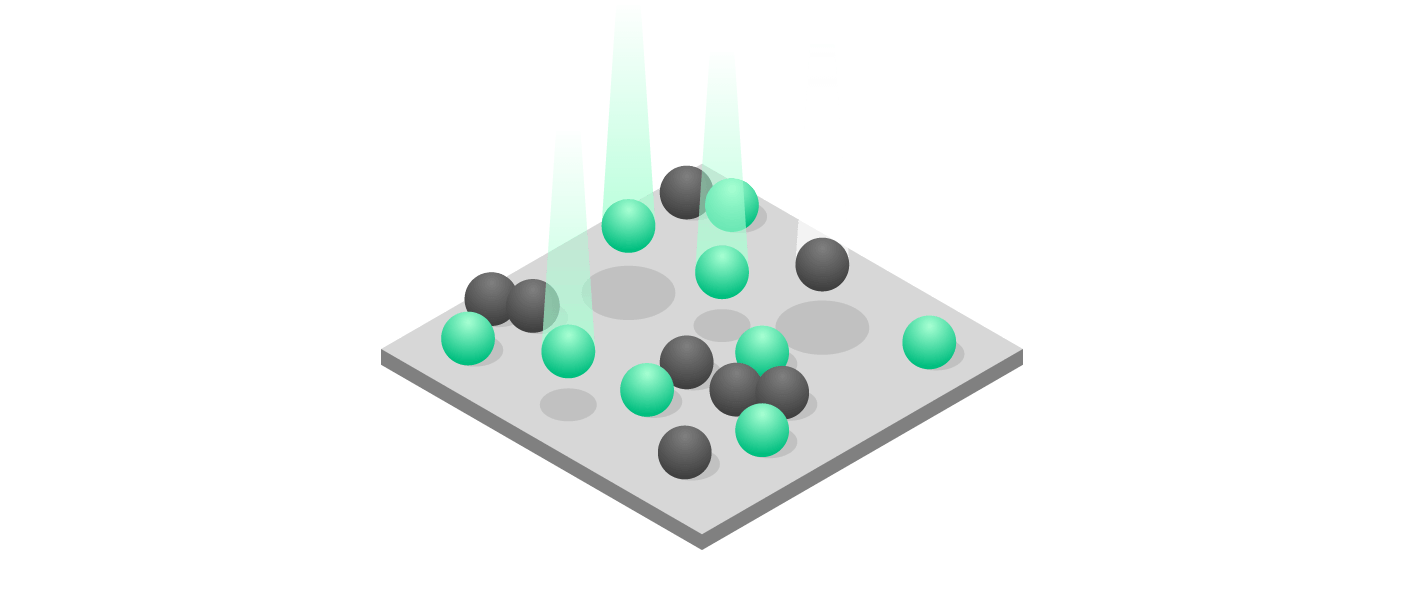

Nitrogen or other atoms are accelerated and introduced into the diamond via ion implantation. This method allows the nanometer precise depth positioning of the resulting color centers.

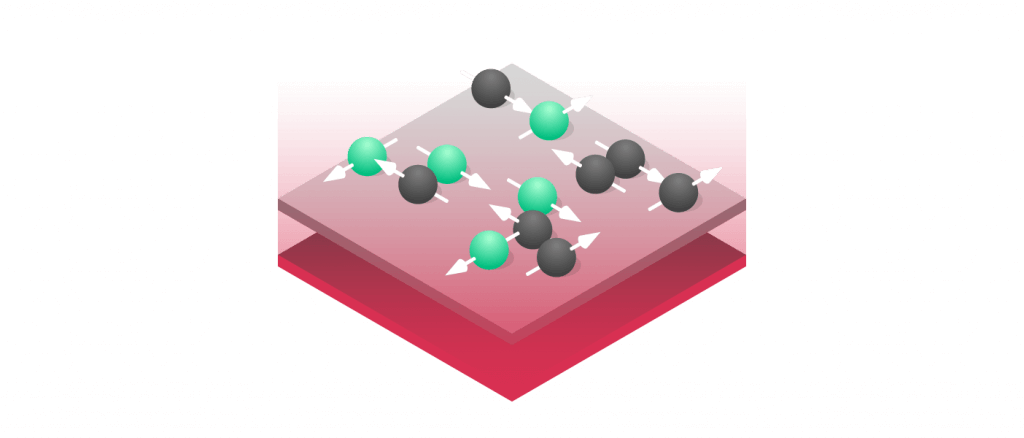

To form color centers such as the NV, the diamond is annealed in vacuum at high temperatures of ~1000 °C for several hours.

The resulting diamond and color centers are analyzed on the nanoscale using quantum optical microscopes. This ensures a reproducible production process.

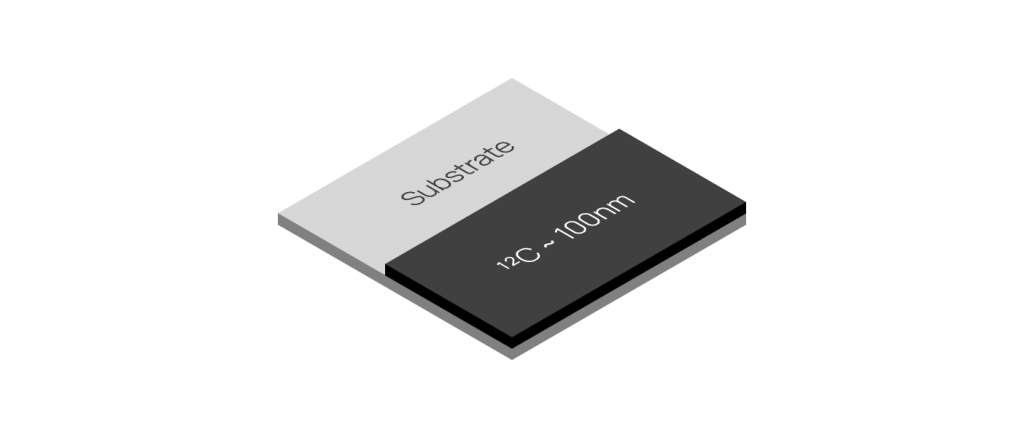

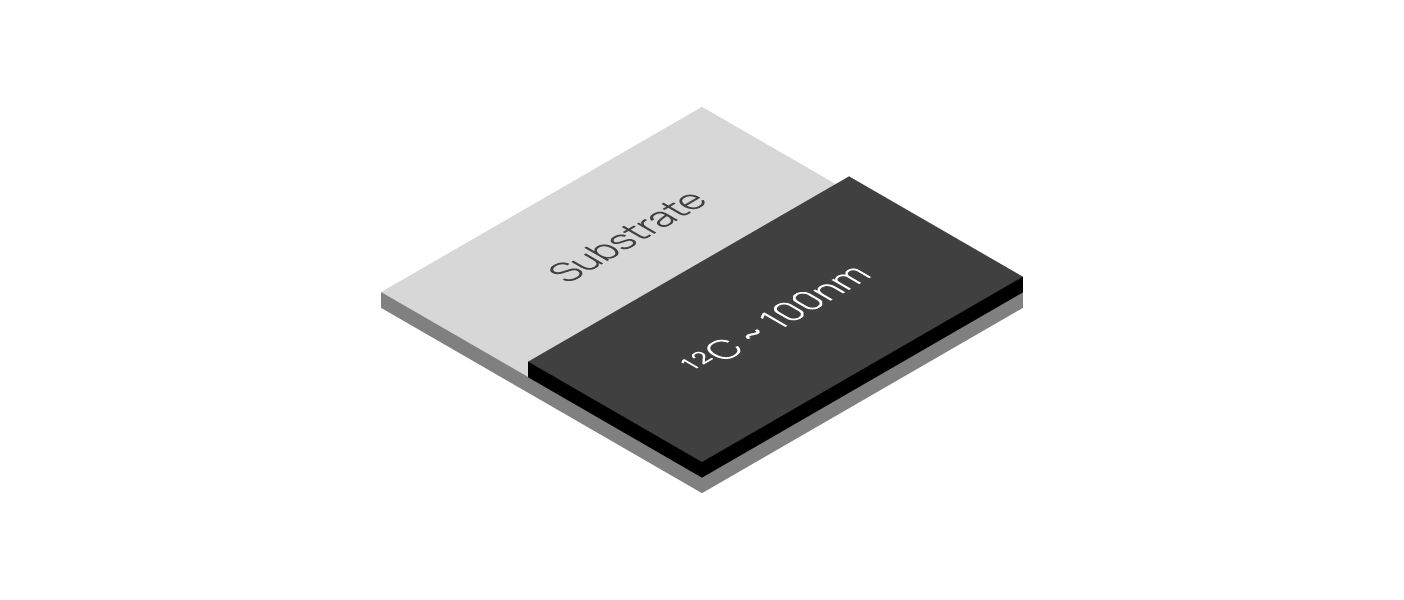

CVD Diamond Growth

CVD (chemical-vapor-deposition) diamond growth allows the controlled generation of diamond layers. The diamond matrix, built from carbon atoms, forms the basis of all quantum technological appliactions. The additon of methane to the process provides carbon atoms for successful growth of diamond. During the process, it is possible to add nitrogen as dopant, resulting in grown-in NV centers. As needed, process steps 02 & 03 can therefore be omitted since the NV centers are created during the growth.

12C Purified Layers

13C Enriched Qubit Layers

Ion Implantation & Annealing

To create color centers such as the NV center, ion implantation of nitrogen with subsequent high temperature annealing is a common technique. Nitrogen ions are accelerated towards the diamond and introduced to depths up to 12 nm for an acceleration energy of 5 keV. This technique allows the precise control on depth as well as density of the NV centers ranging from isolated single centers up to dense ensembles of NVs. High temperature annealing at 1000 °C in vacuum allows the migration of nitrogen with created vacancies to form NV centers.

FAQs

How can isotopically enriched diamond be produced?

Isotope-enriched diamond is produced using artificial diamond production processes. Typically, these are the high-pressure, high-temperature (HPHT) process and the chemical vapor deposition (CVD) process. The isotope ratio is determined during diamond production and cannot be changed afterwards.

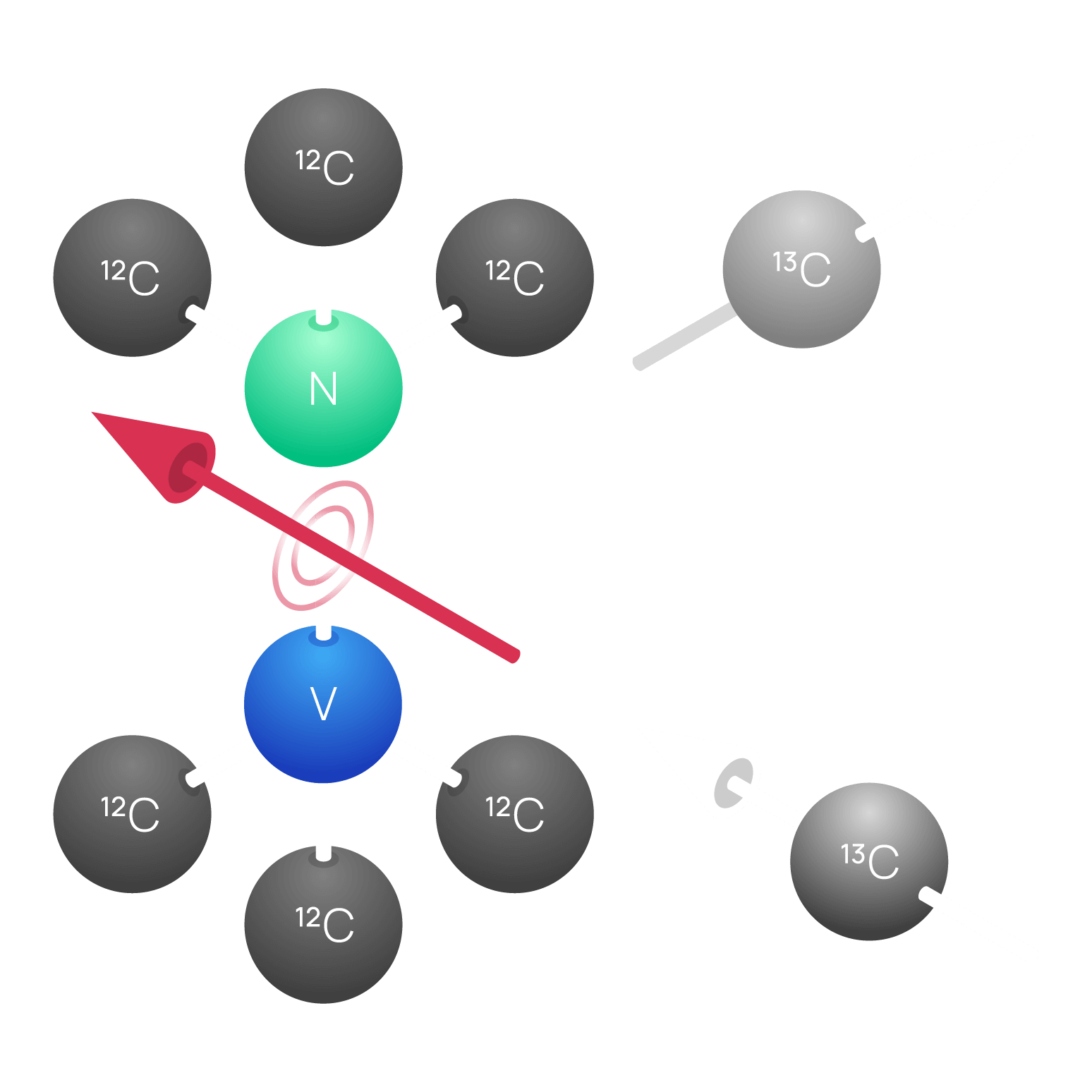

Why do we need isotope-enriched diamonds?

The isotope 13C has a nuclear spin of I=1. In the case of a quantum sensor, this nuclear spin in the diamond leads to interference during the measurement. The absence of this source of interference therefore leads to improved sensitivity. On the other hand, quantum computing relies precisely on these nuclear spins naturally present in the diamond, as they are naturally well shielded against influences from the environment and can therefore be used very well as qubits in quantum computers.

What is isotope-enriched diamond?

The natural occurrence of the carbon isotope is mainly composed of the two classes 12C (98.9%) and 13C (1.1%). This is also found in natural diamonds. In artificially produced (synthetic) diamonds, this ratio can be manipulated to achieve the desired properties for quantum sensor technology (less 13C) or quantum computing (more 13C).

What is synthetic diamond?

A synthetic diamond is a diamond that was not created naturally in the earth’s interior, but in an artificial way in a laboratory. This material is much purer than natural diamond, as it can be grown for special purposes (e.g. quantum sensing or quantum computing). For most quantum technology applications, the natural diamond material cannot be used due to the large number of color and defect centers present.